GLOW PLUGS

Diesel engines are characterised by a self-ignition at a temperature of more than 650°C. This increase in temperature is caused by air compression inside the cylinder, which, depending on the type of engine, goes from 1 bar, ambient pressure, to 20/30 bar, with the resulting combustion of diesel.

During the ignition phase, however – when the engine, the pistons walls and the combustion chamber walls are cold – a part of the heat produced by combustion is dispersed, thus preventing the self-ignition. Glow plugs function as an additional source of heat in order to compensate for this loss.

After the ignition phase, the heat produced by combustion is able to keep the minimum temperature for self-ignition.

Technology has played a significant role in this process, and progress has been made. Engines with single coil glow plugs of first generation, indeed, did not burn diesel properly, thus emitting black smoke and a smell of fuel until the working temperature was reached

Nowadays, new generation glow plugs, called of "pre-" and "post-heating", reduce considerably consumption and emissions of harmful oxides, thus making engines less noisy and odourless

The double-coil structure of these glow plugs has the merit of this performance: it adjusts the temperature and keeps glow plugs running.

In detail, the first filament allows a self-regulation of the current that passes through it, according to the reached temperature; the second one is an incandescent filament that, only for a few seconds, allows to reach the temperature of 1.000°C, thus triggering the auto-combustion.

This combination increases the glow plug's longevity and it guarantees its reliability with any weather condition.

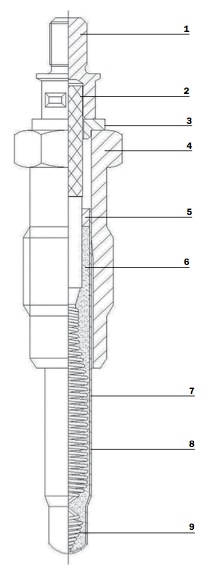

SELF-REGULATING GLOW PLUGS

- Threaded Terminal

- Electrode

- Insulation disc

- Plug body

- Seal ring

- Magnesium Oxide

- Sheath resistive Stem

- Regulating Spiral

- Heating Spiral

Structure and characteristics of a glow plug

Modern glow plugs are composed by a plug body, an heating element (where there is a regulating and a heating spiral) and a terminal for the electrical connection.

The heating element is pressed into the plug body in order to prevent a gas leak, while an insulation disc keeps it separate from the terminal, for the electrical connection.

Glow plugs are powered by a battery, and they are controlled by a transformer.

Regulating and heating spiral

The fundamental principle of modern glow plugs consists in the combination of an heating and a regulating spiral, joined into a sheath resistive stem and connected in series among them.

The heating spiral, welded on the sheath, is the front of the glow plug.

The regulating spiral, fixed on the terminal of the connection, is the rear part; it increases its electrical resistance according to the temperature; thus allowing the adjustment of the current and of the temperature itself.

Protection of the heating and regulating spiral

Spirals are pressed and electrically insulated through magnesium oxide, which is mechanically pressed itself inside the sheath: in this way, the sheath resistive stem can support every vibration.

The loops of a spiral shall be a minimum of a few tenths of a millimetre apart: magnesium oxide prevents that they touch themselves, in order to avoid a short circuit that could destroy the sheath resistive stem.